Gustavo Hernández

Gustavo Hernández

Table of Contents

4 Wind electricity

generation – State of Art

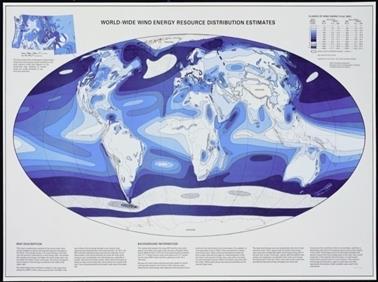

5.1 Analysis of the wind available

technologies

5.2 Micro-generation promotion

5.4 Detailed analysis and specifications

5.4.6 Environmental considerations

5.4.11 On-roof downtown projects

6.1 Public safety considerations

7.4 Comparison of alternatives and

evaluation

7.4.4 Comparison – Conclusions on alternative scenarios

8.4.1 Emission, Economy Stimulation, Saved Energy and Job

Creation

Appendix A – Network development

Appendix B – Micro-generation growth in

Alberta

Appendix C – Summary of areas to consider

for wind generation turbines

Appendix D – History and Potential of

micro-wind turbines in North America

Appendix F – EROEI for different

technologies

Appendix G – Analysed wind turbines

Appendix I – NPP, SPP and Downtown Edmonton

Appendix K – Wind, buildings and turbulence

Appendix L – On-roof wind project around the

world

Appendix M – Solar Photovoltaic (PV)

analysis

M.3 Analysis of the technology in Alberta

M.3.6 Micro-generation promotion

Appendix N – Risk analysis for the

comparative alternatives

Appendix O – RETScreen Financial Analysis

comparison Wind Vs. Solar Panel

Appendix P – Business case with different

ROR and manpower considerations

Appendix Q – Risk assessment for the four

on-roof project alternatives

Appendix R – Business cases for the four

on-roof alternatives

AUC: Alberta Utilities Commission

DoE: DOE: Department of Energy

ERCB: Energy Resources Conservation Board

EROEI: Energy Return on Energy Investment

FAT: Factory Acceptance Test

GHG: Greenhouse Gases

GoA: GOA: Government of Alberta

GW: Giga Watt

GW/h: Giga Watt per hour

HAWTs: Horizontal Axis Wind Turbines

ktGHG: kilo tonne of GHG

kW: kilo Watt

kW/h: kilo Watt per hour

MG: Micro-generation

MGr: Micro-generator

MW: Mega Watt

MW/h: Mega Watt per hour

NPP: North Petroleum Plaza

OE: Office Ecology

OET: Office Ecology Team

PBL: Planetary Boundary Layer

PJ: Peta Joule

PJ/y: Peta Joule per year

PV: Photovoltaic or Solar Photovoltaic

SAT: Site Acceptance Test

SPP: South Petroleum Plaza

SWT: Small Wind Turbine

SWTS: Small Wind Turbine System

VAWTs: Vertical Axis Wind Turbines

W: Watt

Figure 4.1 HAWT turbines

Figure 4.2 VAWT turbines

Figure 4.3 Special design turbines

Figure 5.1: Noise sources in the

HWAT rotor plane

Figure 5.2: A

specification of up to 55 decibels (dBA) allows not to be intrusive and to work

under Edmonton city’s bylaw and international recommendations.

Figure 5.3: Time is service

probability as function of the wind speed on NPP roof.

Figure 5.4: Total estimation

installed height for the studied turbines

Figure 5.5: Wind

Frequency Orientation distribution for NPP location 50 m of altitude.

Figure 5.6: Wind

Frequency Speed distribution for NPP location at 50 m of altitude.

Figure 5.7: typical curves for different analysed turbines

and the annual wind speed frequency distribution on NPP.

Figure 5.8: Total energy

efficiency estimation for the analysed turbines considering the on-roof

application in NPP. The average value, 20.5%, is shown as the red line.

Figure 5.9: Cost of

wind project per kW of nominal capacity

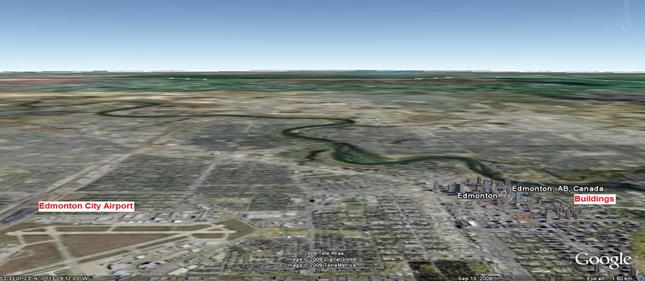

Figure 6.1: view of

Edmonton City Airport and NPP and SPP buildings

Figure 7.1: milestones in

the development of the project

Figure 9.1: Total capital

expenditure and project present value as function of the kW installed (two

identical turbines).

Figure 9.2: Annual savings for wind

electricity generation is represented in the yearly money paid by the GoA. The

different curves represent different nominal wind turbine capacities.

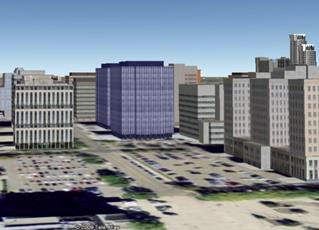

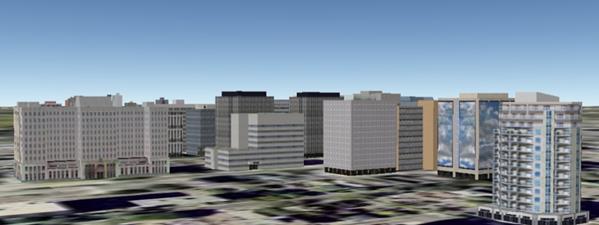

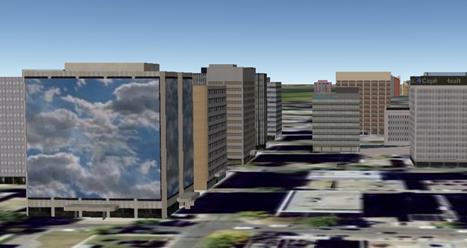

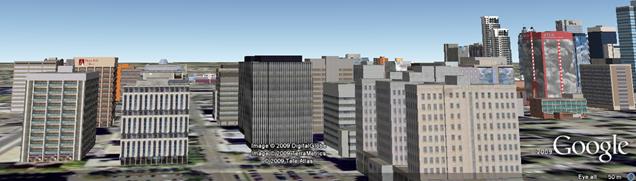

Figure I.1: Downtown Edmonton

Figure I.2: NPP and SPP buildings south east view

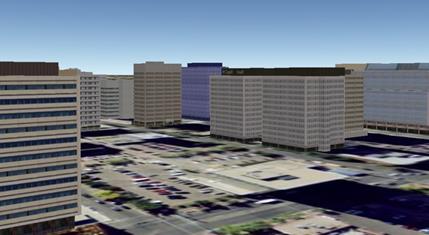

Figure I.3: NPP and SPP buildings south view

Figure I.4: NPP and SPP buildings south west view

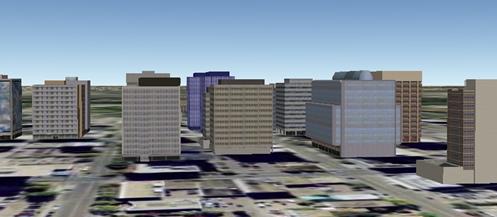

Figure I.5: NPP and SPP buildings west view

Figure I.6: NPP and SPP buildings north-west view

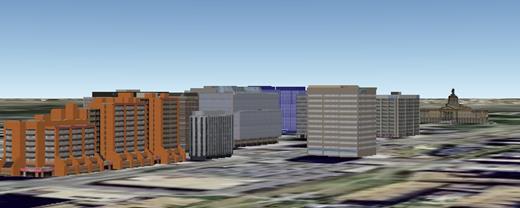

Figure I.7: NPP and SPP buildings north view

Figure I.8: NPP and SPP buildings north east view

Figure I.9: NPP ground view

Figure I.10: area viewshed for the turbines

Figure I.11: The hub height under the turbine is negligible this

specification

Figure I.12: Minimum distance to perceive the

turbine

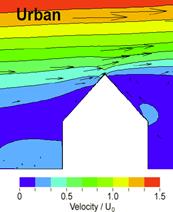

Figure K.1: Wind-obstacle interaction for the turbulence

formation and wind speed variation

Figure K.2: Neighbourliness consideration in the wind

profile modification

Figure K.3: NPP and SPP show a

relatively clean wind interaction with the neighbourhood buildings

Figure L.1: Examples of on-roof

turbines around the world

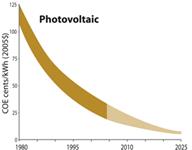

Figure M.1: PV cost evolution

Figure M.2: Cost of the electricity

by technology

Figure M.3: Visual impact of PV technology

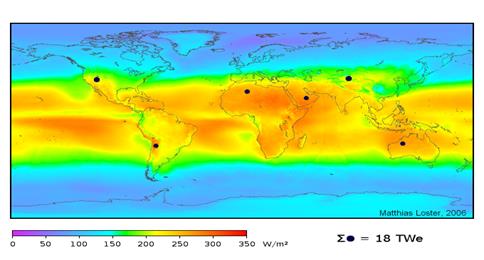

Figure M.4: Solar radiation distribution around the

world

Figure M.5: Canada and Alberta solar radiation

distribution

Figure M.6: EPCOR headquarters PV installation

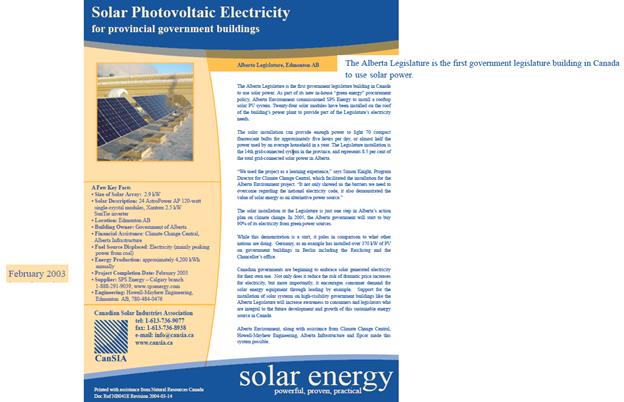

Figure M.7: PV project in the Alberta Legislature

Figure

O.1: Financial Analysis - Solar Panel project

Figure

O.2: Financial Analysis – Wind Project

Figure S.1: GoA alternative, it

takes around 476 business days to be completed

Figure S.2: Eng alternative, it

takes around 479 business days to be completed

Figure S.3: Com and Part

alternatives, they take around 396 business days to be completed

Table 4.1: Annual electricity and energy consumption in

Alberta for 2006 in different sectors [45]

Table 4.2: Annual electricity and energy consumption in

Alberta in 2008 [21]

Table 5.1: The following

table presents the average wind farms efficiency in 2007 [2] [80]

Table 5.2: Avian mortality by

technology

Table 5.3: GHG emission by

technology

Table 5.4: Micro-generation

shows great potential as job creator

Table 6.1: ISO 1996-1971

Recommendations for Community Noise Limits

Table 7.1: Sustainable ranking for

different technologies

Table 7.2: Assess impact

evaluation table

Table 7.3: Assess

impact evaluation for the different four alternatives

Table 7.4: Risk

assessment table

Table 7.5: Risk

assessment outcome for the four different alternatives

Table 7.6:

RETScreen summary for the ecominic comparison of the four alterantives

Table 7.7:

RETScreen summary for the ecominic comparison of the four alterantives.

Reasignation of funding

Table 8.1: Assess

impact outcomes for the four alternatives developing the on-roof project

Table 8.2: Risk

impact outcomes for the four alternatives developing the on-roof project

Table 8.3: Business

cases summary for the four wind on-roof project development alternatives

Table 8.4: Summary of energy and

emission to save by micro-generation technologies

Table 8.5: Summary of energy and

emission to save associated to this on-roof project

Table 8.6: schedule for the

development of the on-roof wind project for the four different alternatives

Table 9.1: GoA funding break down

Table 9.2: Minimal

specification for the turbines

Table A.1: Stakeholders summary

Table B.1: Micro-generation development in Alberta up to June 2009

under the new regulation

Table E.1: Comparison between HAWT and VAWT technologies

Table F.1: EROEI index for

different technologies

Table G.1: Summary of the studied

turbines

Table H.1: Common Noise Production Levels

Table M.1: Wind and PV technology development in

Alberta, Canada and the World

Table M.2: Summary of wind and PV technology

development in Alberta, Canada and the World

Table M.3: Summary of job creation rations for wind

and PV technologies

Table M.4: GHG emission for

different technologies in Alberta according to RETScreen software

Table

N.1: Risk analysis details for the four alternatives

Table

P.1: On-roof wind project, business case 1

Table

P.2: On-roof wind project, business case 2

Table

P.3: On-roof wind project, business case 3

Table

Q.1: Risk analysis details for the four in-roof wind alternatives

Table

R.1: Wind project cost estimations

Table

R.2: Energy and money saved over the time

Table

R.3: Money recovered over the time

Table

R.4: Summary of the business case for the DoE alternative

Table

R.5: Summary of the business case for the Eng alternative

Table

R.6: Summary of the business case for the Com alternative

Table

R.7: Summary of the business case for the Part alternative

Many people have participated directly or indirectly in this project.

We conducted consultation and discussions with stakeholders; this process was essential

for the development of this study, knowing the available technology and sensing

of the interest in the project. The technical specifications recommended are

based on these discussions trying to meet several requirements for the special

conditions of the project as well as to be the most practical and realistic

possible according to the available technology today.

The images in the study, except those where is shown NPP and SPP, were

obtained from Google images.

I'd like to thank people from OE Team that they collaborated polishing

this study, the associated presentations and they provided ideas and

information in the process of improvement (especially Carmen Gilmore, Chris

Arnot, Henry Dakurah, Kathleen Pate, Kristin Stolarz and Maurine Mullins).

Finally, I'd like to thank people from the GoA and CASA, who they allowed me to

work and present this project (Andrei Nikiforuk, Matthew Machielse, Tim Grant

and Kerra Chomlak).

This study represents the feasibility study for the development of the

wind turbine micro-generation project on roof buildings. The three main

objectives of the project is to provide a show case project supporting the

micro-generation development in Alberta, to show the commitment of the

Government of Alberta and the Department of Energy as well as leadership

initiatives in environmental friendly source of energies. This study represents

a guide and a point of start for the final project specifications. This

document is the support of the presentation document (Power Point and Executive

Summary) and it does not represent the final recommendations, which should be

reached with more extensive discussions.

This study was carry on during the term of almost one year, but it is

based on background experience and knowledge of the different actors that they

participated. During this year, the technology, economic conditions and more

have changed. The project, in any subject, was updated constantly during this

year based on new evidence and boundary conditions. Many cares was taken to

maintain the logic and congruent sequence of data, information and outcomes. In

case of errors, omission, unclear or uncompleted data or information, the

complete responsibility is assumed by the author of this study.

January 2010

Executive Summary

Objectives

This study examines

the promotion of micro-generation in Alberta through an inspiring example of

wind generation. In addition, the Department of

Energy (DOE) has the opportunity to demonstrate, once again, leadership and

commitment to energy management, technology development, environmental

protection and pro-active actions. Few opportunities are present over the time

to demonstrate all this commitments.

Background

Micro-generation is the term used to describe

generation of environmentally-friendly electricity on a small scale, i.e. for

individual customer use. Alberta’s Micro-generation Regulation (announced in February

2008 and in force in January 2009) is the set of rules that allows electricity

customers to generate their own environmentally friendly electricity and

receive credit for any power they don’t use and send back to the electricity

grid.

This

regulation is based in the promotion of renewable and alternative sources of

energy which present many benefits to society, market, environment, etc. These

benefits include: efficiency and conservation, environmental considerations,

business development, job creation, stabilizing electricity prices, decreasing requirements

for transmission lines, etc.

Recommendations and Conclusions

We

recommend that the DOE provide the funding and personnel to develop the wind micro-generation

project in Edmonton downtown, preferably in North Petroleum Plaza (NPP) and with

the cooperation of Alberta Environment in South Petroleum Plaza (SPP).

Alternative on-roof wind

partner development offers the best value for the DOE, taking into account all

factors: impact, risk, sustainability, investment, and investment recovery. Wind

generation affords meaningful, sustainable development, promotion of

micro-generation and positive impact on all stakeholders (including all Albertans).

It will demonstrate the Government’s commitment to bolstering micro-generation business

development in Alberta.

From a Government of

Alberta (GOA) perspective, this project presents a positive presence in the

Government core in downtown Edmonton, meets all the characteristics to promote

the use of micro-generation in Alberta, and shows the commitment of the DOE and

the GOA to efficient use of resources. In addition, the project presents a

positive present value in its life doing that the on-roof wind project will pay

for itself.

This document represents the feasibility study of the

on-roof wind generation facility based on NPP and SPP towers developed by the

DOE’s Office Ecology Team (OET).

The DOE has the

opportunity to model the efficient use of energy and available micro-generation

resources. This initiative develops a multiple gain scenario where multiple

players collect several benefits in a positive feedback:

-

Micro-generation promotion:

o

Improves the electricity generation

matrix in Alberta;

o

Promotes the use of alternative and

renewable sources of energy;

o

Promotes energy efficiency;

o

Helps reduce electricity costs;

o

Helps decrease electricity cost

volatility; and

o

Decreases energy losses in transmission

lines.

-

Social:

o

Helps educate citizens on Energy

Efficiency and Energy Conservation;

o

Increases micro-generation businesses;

o

Increases employment;

o

Increases community commitment and

awareness of energy efficiency and use; and

o

Increases Research and Development

(R&D) initiatives in Alberta;

-

Economics:

o

Saves money in Micro-generation

promotion and education;

o

Reduces electricity consumption in

the proposed buildings; and

o

As micro-generation technology:

-

Helps reducing wholesale electricity

price and volatility;

-

Increase the energy efficiency;

-

Helps in the development of micro-generation

businesses; and

-

Help in job creation at all levels

(research, management, maintenance, operation, administration, etc).

-

Environment:

o

Saves emission;

o

Promotes the use of renewable and

alternative sources of energy; and

o

Contributes to provincial targets

achievement in emissions reduction.

-

DOE and GOA:

o

Shows the commitment of DOE and GOA

through an inspiring example; and

o

Shows DOE and GOA are taking the

initiative in energy efficiency, renewable and alternative energy use, and energy

cost reductions that face Albertans.

The objective of this

analysis and comparison is to maximize the following:

1.

Promote micro-generation

2.

Improve energy use and conservation

3.

Promotion energy efficiency

4.

Promote Greenhouse Gas (GHG) emissions reduction

5.

Promote micro-generation business development

6.

Effective investment of government monies

7.

Risks minimization

8.

DoE and GoA commitment

9.

DoE and GoA initiative

Micro-generation is the term used to describe

generation of environmentally-friendly electricity on a small scale—for

individual customer use. In Alberta, micro-generation is one megawatt or less

of electricity generation that is connected to the distribution system.

Alberta’s Micro-generation

Regulation is the set of rules that allows electricity

customers to generate their own environmentally friendly electricity and

receive credit for any power they don’t use and send back to the electricity

grid. Appendix B presents details of micro-generation installation under this

regulation.

Micro-generation use produces significant positive

effects in energy use and in the electricity market:

·

Increases the efficiency in the residential sector

as well as energy use in rural areas.

·

Increases renewable and alternatives source of

energy. Micro-generation is the base of all the technologies allowed for

micro-generation and all of them help in emission reduction.

·

Decreases energy consumption: the so-called “second

effect” produces around a 6% decrease in electricity consumption due to

awareness around electricity use.

·

Decreases losses in transmission lines: electricity

is generated on site, eliminating the need for transmission lines (between the

6 and 8 % of the electricity generated in Power Plants is lost due transmission

and distributions lines losses).

·

Stabilizes and decreases the cost of the

electricity: on peak hour cost of electricity has a huge impact in daily

electricity price; micro-generation helps reduce on peak demand, and has a

secondary effect of increasing awareness in consumption along with reducing the

on peak electricity cost.

·

Micro-generation business: increase the number of

micro-companies offering for micro-generation technology, installation and

maintenance.

·

Although there is worldwide consensus in favour for the wind

generation development, many voices can be heard stressing the weaknesses of

wind generation technology such as increased electricity price, the need for backup

because of the unpredictability of the resource, etc. This awareness does not

apply for micro-generation due to the scale of the technology.

Over the years, the

worldwide contribution for the development of wind technology offers a

widespread technical possibility to use this technology for electricity

generation. Nowadays, there are wind turbines with a capacity of a few Watts (W)

to Megawatts (MW), turbines for applications in extreme weather conditions,

top-roof turbines, in a hill, on-shore and off-shore, etc.

In December 2008,

Canada counted with two Gigawatts (GW) of installed wind capacity [2],

increasing this number by 46% per year during the period of 2004-2008. Alberta is

one of the leaders in Canadian wind development with a capacity of 540 MW of

installed power capacity. In addition, Alberta had one of the better wind

capacity coefficients in Canada: 35% wind in 2007 and 32.4% in 2008 [2]. Finally,

the Alberta Electric System Operator (AESO) had 81 wind

projects in its queue in Alberta, representing nearly 11,714 MW [21].

If Alberta installed wind turbine in all appropriate sittings, Alberta’s

maximum estimated wind capacity, at the current technical development, is

400,000 MW with an electricity production of 2,100,000 GWh/y or 7,500 PJ/y. If

we compare these numbers with the annual electricity and energy consumption by

sector in Alberta, the importance in the development of this technology provincially

and country wide is evident.

|

Sector |

Annual electricity consumption [GWh] |

Annual energy consumption [PJ] |

|

Residential |

6,810 |

179 |

|

Transportation |

110 |

405 |

|

Industrial |

27,900 |

832 |

|

Commercial |

13,500 |

154 |

Table 4.1: Annual electricity and energy consumption in Alberta for

2006 in different sectors [45]

|

Item |

|

|

2008 Electricity Consumption [GWh] |

70,000 |

|

2008 Generation Capacity [MW] |

12,300 |

Table 4.2: Annual electricity and

energy consumption in Alberta in 2008 [21]

Different publications [12], [17],

[20],[26] and [28] analyse wind resources assessment models, site selection

models and aerodynamic models including wake effect, leading discussions about

existing performance and reliability evaluation models, various problems

related to wind turbine components (blade, gearbox, generator and transformer)

and the grid system development for integrating the wind energy system. In

particular [17] has an extensive database of referred studies for each concern

associated to wind technology.

Basically, two different

types of wind turbines exist, the horizontal and vertical axis wind turbines

(HAWTs and VAWTs); the horizontal axis wind turbine is the most common type. Several

sub-classifications exist for them. Figures 4.1, 4.2 and 4.3 show the most

common turbine classification.

|

a) Classic |

b) On-roof design |

c) Multiple blades |

d) Integrated |

Figure 4.1: HAWT turbines

|

e) Helical |

f) L-shaped |

g) Darrieus |

h) H-rotor |

Figure 4.2: VAWT turbines

|

i) Magnus effect |

j) Floating |

k) Integrated |

l) Helical on-roof |

Figure 4.3: Special design turbines

The first windmill was a

VAWT; later HAWTs received most attention, but some scientists [32] claim that

the HAWT is not obviously better than the VAWT just because it was randomly

picked long ago for large-scale development.

Appendix C presents more

details in the analysis of wind turbines.

Evidence

indicates that people view small and large wind turbines the same even though

they have very different characteristics [82][83]. The technology principles are

the same, but both industries are different, with different boundary conditions,

cost, market and goals.

Small

Wind Turbines (SWT) are classified as:

·

Mini wind turbines with a rated power output from

300 W up to 1000 W (1 kW);

Capitalizing on the potential market in Alberta (not

possible in practical point of view nowadays) would result in the installation

of over 100 MW of Small Wind Turbines System and GHG emission reductions of

over 250 ktGHG per year [2]. Each MW of installed wind power in Alberta today, represents

an emission reduction of 2.5 ktGHG per year.

At the present, the market

for SWTs in Canada is relatively small, although it has experienced some growth

in the past five years [2]. A survey of retailers, distributors and

manufacturers of SWTs revealed the following:

·

Annual Sales. It

is estimated that current annual sales of SWTs are in the range of 600 to 800

units per year. This represents roughly $3.5 million in annual sales, including

$2.3 million for mini wind turbines and $1.2 million for small wind turbines.

Appendix D shows the evolution over the time of

micro-wind in North America.

There

is some concern in the use of HAWT technology for on-roof wind project. These

concerns focus on the effect of the turbulence on the turbine performance,

durability, control performance, maintenance cost, vibration, etc [36]. New

on-roof design for HAWT removes those weaknesses (figure 3.1-b), although some

projects were developed with success, the commercialization period of this

technology did not occur. VAWT technology overcomes most of those weaknesses,

but it adds others.

An

omni-directional turbine can be situated at places where the wind is turbulent

and where the wind  direction changes often. For this reason, VAWTs

have an advantage over HAWTs in high mountain areas, in regions with extremely

strong or gusty winds and in urban areas [35][37]. Investigations indicate a

clear advantage in using VAWTs at rooftops [36]. Furthermore, the VAWT is less

noisy than the HAWT, which becomes even more important in urban areas [35] as

well as less dangerous for birds [17].

direction changes often. For this reason, VAWTs

have an advantage over HAWTs in high mountain areas, in regions with extremely

strong or gusty winds and in urban areas [35][37]. Investigations indicate a

clear advantage in using VAWTs at rooftops [36]. Furthermore, the VAWT is less

noisy than the HAWT, which becomes even more important in urban areas [35] as

well as less dangerous for birds [17].

VAWTs

appear to be advantageous to the horizontal axis wind turbine in several

aspects for roof applications. Reports advise of the inconvenience to install a

HAWT on a building roof [36] due to high turbulence, less life of the turbines

and less energy production. However, the use of VAWT in cities has increased

due to the natural advantages of VAWT technology for this market sector. Around

the world, multiples studies have been conducted (Ontario [39], Brampton,

Canso, Kingston, Marathon, Wawa, Wolf [44], Germany [40]) and roof mounted

VAWTs have been proposed as part of the energy source for the Freedom Tower in

New York City [38].

The

vertical rotational axis of a VAWT allows the generator to be located at the

bottom of the tower. This makes installation, operation and maintenance much

easier. The tower can be lighter for a VAWT since the nacelle is excluded,

which reduces structural loads and problems with erecting the tower [41]. The

generator design can be focused on efficiency, cost and minimising maintenance.

Furthermore, the control system can also be located at ground level

facilitating access.

The

blades of a HAWT have to be self-supporting since they are only attached at the

root. The blades of a VAWT are supported by support arms, which usually are

attached to the centre of the blades. However, the support arms add extra

structure and mass to the turbine. For a larger blade area, more material is

used. Mass production of VAWT blades would imply low production costs since

their shape makes them easy to fabricate in large numbers compared to HAWTs

[41].

More

discussions about the HAWT and VAWT differences are exposed in Appendix E where

a summary is presented comparing HAWT and

VAWT technologies.

Wind technology

presents important characteristics in the promotion of micro-generation

technologies and renewable sources of energy.

The effect in the community

is extremely large at the start of the project, and it persists over time with

the same intensity for several generations. The movement, and its variation,

produces a double effect as it captures people’s attention to this technology.

To settle the wind

turbine in the downtown of a populous city stress significantly the promotion

of the technology and micro-generation as a general concept.

In 1919 the physicist Albert Betz

showed that for a hypothetical ideal wind-energy extraction machine, the

fundamental laws of conservation of mass and energy allowed no more than 16/27

(59.3%) of the kinetic energy of the wind to be captured [28][46]. This Betz' law limit can be approached by modern turbine designs which

may reach 70 to 80% of this theoretical limit.

Today, the available wind energy conversion

efficiency reaches about an average of around 40% in modern wind turbine types.

The common value for most of installation is between 30 and 35% in wind farm

and between 20 and 32 % for on-roof applications. Considering the losses due to

energy operation of the turbine components, this efficiency decreases in around

4 % more [35] [36] [37]. The following table presents the average wind farms

efficiency in Alberta, Canada and the World for 2007.

|

|

Alberta |

Canada |

World |

|

Wind

efficiency for electricity generation [%] |

32.9 |

32.8 |

34 |

Table 5.1: The following table presents the average

wind farms efficiency in 2007 [2] [80].

Another important

concept related to the efficiency of the different technologies is the called

The Energy Return on Energy Investment (EROEI) index; this index shows the

relationship between these two amounts of energy. Appendix F presents the EROEI

for different technologies for comparison; wind technology has an EROEI between

10 and 18.

Thirty-five different

turbines/technologies were taken as reference to compare and work in the

selection of specifications; the companies which provide these turbines

provided significant expertise, comments and discussion for the project

estimation (cost, time, risk, etc.) and stakeholder network development. The

summary of these turbines is presented in Appendix G.

Noise from wind turbines (when

active) may interfere with the lives of animals beneath the wind turbines. Wind

turbine noise is one of the major hindrances for the widespread use of wind

energy [8][77][78]. In order to reduce wind turbine noise the source mechanisms

must be known. For a modern large wind turbine, aerodynamic noise from the

blades is generally considered to be the dominant noise source, provided that

mechanical noise is adequately treated [11].

Due to the large number of

applications (e.g. wind turbines, airplanes, helicopters, fans), the

characteristics of airfoil noise have been investigated extensively in both

experimental and theoretical studies. Both inflow-turbulence and self-noise

mechanisms were considered and the dependence on parameters such as flow speed,

angle-of-attack, radiation direction, and airfoil shape was characterized.

These studies formed the basis of several semi-empirical wind turbine noise

prediction models, which were validated by comparison to field measurements.

Since the field results only provided the overall sound level of the turbine,

the relative importance of the different mechanisms was determined mainly on

the basis of the predictions. In some studies inflow-turbulence noise was

regarded to be the dominant source, while others considered trailing edge noise

to be dominant. In another case the turbine noise in different frequency ranges

was attributed to mechanical noise, trailing edge noise, tip noise, and

inflow-turbulence noise.

Figure 5.1: Noise

sources in the HWAT rotor plane.

In

[37] is reported a serious concern related with on-roof turbine and the noise

annoyance that they present. Appendix H presents the common noise production

levels.

The

VAWT technology, specifically the H-rotor turbine, is expected to produce much

less noise than a HAWT technology. There are two main sources for wind turbine

noise; aerodynamic noise from the turbine’s blade tips and mechanical noise

from the drive train components. The aerodynamic noise increases with

increasing blade tip speed of the turbine. A VAWT usually has a tip speed which

is approximately half the tip speed of a HAWT and it therefore produces less

aerodynamic noise. Since a VAWT has the drive train components at ground level,

the possible noise from these parts will not propagate as easily as when the

drive train components are situated on top of the tower. The VAWTs rotate

slower than a HAWT of the same size; it will therefore produce less noise than

the HAWT [17][41]. The following figures show the noise levels for two

different turbines; in the left side a VAWT turbine noise level is represented

(OE-8) and in the right side a HAWT turbine noise level is presented

(OE-1).

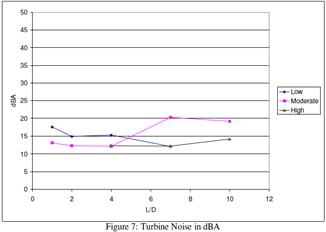

Figure 5.2: A specification of up to 55 decibels (dBA)

allows not to be intrusive and to work under Edmonton city’s bylaw and

international recommendations.

This is a subjective concept; the visual impact of wind farm is

considered positive (Prince-Edward Island [2]) in some regions but negative in

others (Gaspésie, Quebec [2]).

In the present project, the potential visual impact is inverted; the

showcase characteristics of this project convert the visual impact into a key

role in the project definition. The turbine design must harmonize in shape,

colour, wide, tall, etc. with the building and lateral buildings looking for

the most efficient and harmonious visual impact in the promotion of MG. The

swept area (area covered by the turbine in its rotation) of the turbine should

be enough to capture the attention of people.

Different studies show a detailed assessment in visual impact caused by

wind farms and off-shore projects [6] [7] [8] [58]; for on-roof turbine the

concerns focus on disrupting scenic of old, historical, community buildings,

etc. In the downtowns of modern cities, the concern is diluted by the

characteristics of the cities themselves (essentially moderns and tall

buildings).

The

first step in maximizing the on-roof wind positive visual impact is to map the

locations from which the turbines would be visible. These locations, defined as

the set of points from which an observer could see any of the turbines on a

clear day, are collectively known as the viewshed. Due to the NPP and SPP height

in comparison to neighbouring buildings, the turbines on-roof NPP and SPP do

not offer viewshed intersections with other buildings. Taller buildings in

downtown Edmonton do not need consideration because they are located as far as

one kilometre away. Taller buildings in downtown area are not allowed because of

Edmonton’s city airport. Appendix I presents figures that show the buildings

location in real proportion size in downtown Edmonton, as well as an analysis

of visual specifications.

A negative effect of wind turbine

visual impact showcase is the time during the turbine is not turning; a wind

turbine doesn’t turn all time. If the wind speed is slow, it doesn’t have

enough energy to move the turbine. This state represents a negative effect as

showcase. This minimum energy depends of multiples factors such as kind of

turbine, turbine power, installation, etc; the project design must maximize the

time that the turbine is spinning. The following figure shows the time in

service probability as function of the wind speed in on NPP roof for the four

seasons and the annual average. The figure shows that for example for a cut-in

of 3 m/s the turbine will be working around of 70% of the time during the

summer (17.8 hours per day) and 85% during the winter (20.4 hours per day).

Figure 5.3: Time is service

probability as function of the wind speed on NPP roof.

As summary for visual impact

specifications:

-

A swept area between 6.3 and 125 m2;

-

10 meters maximum height;

-

1.4 meters minimum turbine height (without hub);

-

The turbine colour must following Canadian Aviation Regulations; when

it is possible, it should be some colour

which maximizes the contrast with the white, grey and light blue colour of the

sky;

-

The turbine colour must following Canadian Aviation Regulations; when

it is possible, the turbine must have illumination during the night fed by the

same system (the light should be on when the turbine is spinning);

-

It should be study the psychological effect for the population in the

change of colour light if the turbine is spinning or not; and

-

Cut- in 3 m/s, maximizing the time turning of the turbine.

The following figure shows the

total estimation installed height for the studied turbines:

Figure 5.4: Total estimation

installed height for the studied turbines

The results of many studies [14][10][71] [72] [73]

[74] suggest that:

·

Wind

farms kill millions of birds yearly around the world, and the high mortality of

rare raptors is of particular concern; a greater kill of large birds, raptors and predators is detected in wind farms; raptors glide most of the time

to save energy and they use ascending air currents which often form along

slopes and ridges, where wind plants are often located for the same reason;

·

Wind

farms on migration routes are particularly dangerous, and it is difficult to

find a wind power site away from migration routes because there is no guarantee

that migration routes will not vary;

·

According

to the model of collision probability, the rotor speed does not make a

significant difference in collision probability; the hub is the most dangerous

part, and large birds (e.g. raptors) are at great risk;

·

based

on the field observation of squirrels’ vocalisation (i.e. anti-predator

behaviour), there are behavioural differences between squirrels at the wind

turbine site and those at the control site; and

·

Several

wind farms are erected in the way of migratory routes.

In [72], the researcher goes further and reaches a

relationship between bird fatalities and power generation for different

technologies. The author establishes the existence of the bird and bat

fatalities associated to wind farms, but he argues that this relative concept

changes when we compare the birds killed per kilowatt-hour for different

electricity generation facilities. For fossil fuel power plants the author

considers the bird killed in coal mining, plant operation, acid rain and

mercury. For Nuclear power plants, the author considers the uranium mining and

milling, and plant operation; the result is presented in the following table.

|

Facility |

Avian mortality per GWh |

|

Fossil fuel Power Plant |

0.200 |

|

Nuclear Power Plant |

0.416 |

|

Wind Farm |

0.269 |

Table 5.2: Avian mortality

by technology

The conclusion in aims to show that, instead of the

problems exist in wind farms, the effect is over dimensioned. For wind farms the

effect is magnified because the avian mortality occurs in a very small area. Another

interesting effect, based on the register following this problem, shows that

the avian fatalities are sensitive to time: birds often learn to avoid wind

farms after their first few years of operation.

A special concern is the slaughter of bats; the

University of Calgary has conducted studies due to the high rate of bats killed by certain turbines of

southern Alberta. The study determined that the vast majority of bats found dead below

turbines suffered severe injuries to their respiratory systems consistent with

a sudden drop in air pressure that occurs when the animals get close to turbine

blades. Several universities in Canada are studying procedures and mechanism to

diminish this slaughter of bats [85].

There are not conducted important studies on

slaughter of birds in on-roof wind turbine installations; due to low power

capacity, low swept area in on-roof project development and absence of the main

concern factors, the slaughter of birds doesn’t represent an issue for on-roof wind turbines.

In

relationship with the turbine technology, the VAWT is expected to be less

harmful for birds and bats, since the blades move at a slower pace and the

speed of the blade has been shown to affect the risk for collision greatly

[17][53].

Based on these studies, we can conclude that the

expected avian mortality for the on-roof project is almost null. If some

mortality occurs is more related with fatality than a strict correlation of the

factors.

In

[60][61][62] is presented both experimental and theoretical methods to study

the structural dynamic characteristics of rotor blades to avoid sympathetic

vibration problem. The test revealed that the natural frequencies of flap wise vibrations

are lower than that of the torsional vibrations; flap-wise vibration is the main

vibration of the rotor blade.

Cyclic stresses fatigue the blade, axle and bearing;

material failures were a major cause of turbine failure for many years. Because

wind velocity often increases at higher altitudes, the backward force and

torque on a HAWT blade peaks as it turns through the highest point in its

circle. The tower hinders the airflow at the lowest point in the circle, which

produces a local dip in force and torque. These effects produce a cyclic twist

on the main bearings of a HAWT. The combined twist is worst in machines with an

even number of blades, where one is straight up when another is straight down.

To improve reliability, teetering hubs have been used which allow the main

shaft to rock through a few degrees, so that the main bearings do not have to

resist the torque peaks.

When a HAWT turbine turns to face the wind, the

rotating blades act like a gyroscope [63][64]. As it pivots, gyroscopic

precession tries to twist the turbine into a forward or backward somersault.

For each blade on a wind generator's turbine, precessive force is at a minimum

when the blade is horizontal and at a maximum when the blade is vertical. This

cyclic twisting can quickly fatigue and crack the blade roots, hub and axle of

the turbines.

VAWT vibration is

originated by different physics principles due to the nature of the turbine.

More blades diminish vibration problems, but also decrease the turbine

efficiency.

All engines turning

have an inherent vibration problem, and all consequences associated to this

phenomenon. Special materials, sensors and theories to mitigate the problem

have been developed for hundreds of years. All this technology and procedures

are available today for simple turbines applications. However, heavy turbine

associated to vibration problems could produce important and quick damage in

the turbine basement.

For on-roof turbines,

especial considerations should be taken to avoid vibration transmission through

the building; these considerations should aim structural implications, turbine

life, people welfare and efficiency; real-time monitoring, periodic maintenance

and inspections are mandatory. The vibration transmission/isolation technology

is extremely well known, many industries face similar problems and hundreds of

instruments, software, theories and solution are available. Vibration

transmission to the building represents a problem in itself, but the solution

is available at all levels.

Often

the locations for wind turbines are in exposed locations where they are subject

to icing of the blades. Icing of wind turbine blades can cause a variety of

problems, such as complete loss of production, reduction of power due to

disrupted aerodynamics, overloading due to delayed stall, increased fatigue of

components due to imbalance in the ice load, and damage or harm caused by

uncontrolled shedding of large ice chunks [75][76].

The insect factor has a

similar effect for the wind turbine performance that icing, but it does not

involve public risk. Humid regions are more affected by this phenomenon and it

presents its own particularities. Insects prefer to fly in conditions of high

air humidity, low wind and temperatures above about 10° Celsius. Under these

circumstances, they will increasingly foul the leading edges of the blades.

Stall control is not very accurate in practical

application, and many stall-controlled turbines do not meet their

specifications. The power of wind turbines operating in high winds has been

known to drop for no known reason, causing production losses from 25 to 50%—a

phenomenon referred to as a ‘Double Stall’ or a ‘Multiple Stall’. Some

researchers [76] attributed this multiple power level occurrence to

the insect theory, which states that these levels correspond to different

degrees of insect contamination. A low contamination level decreases the power

by 8% of the design value; while at high levels it can be decreased by up to

55%. In this study a device called a ‘stall flag’ was employed a hinged flap

that opens up in a separated airflow to uncover an individual reflector.

Employing a projector as a light source, they

measured the separated flow from the intensity of reflected light.

The most common solution for reducing the effect of

insects and air pollutants on the blades is to wait for rainfall to wash the blades.

The disadvantage of this system is that the wind turbine must be stopped, so

the resulting power loss will simply add to the losses created by the insects.

Another blade washing technique involves pumping water up through the tower and

spraying it into the wind and through the blade tip, a solution that can be implemented

while the turbine is in operation.

Icing

and insect problems involve a maintenance requirement for the turbines. Because

the Edmonton region is could experience both problems, measures should be

specify for an on-roof turbine:

-

Periodic

maintenance during the periods with the temperature and humidity are

medium/high;

-

Periodic

maintenance, passive (e.g. dark colour for blades to absorb energy) and active

methods de-icing and/or anti-icing.

Furthermore,

problems with icing are less severe with a VAWT compared to a HAWT and less

security distance is required. This is due to the lower rotational speed of a

VAWT but also since an ice part that comes loose cannot get a velocity directed

upwards when leaving a VAWT, as could be the case with ice parts leaving a HAWT

blade.

Wind power consumes no fuel for continuing operation,

and has no emissions directly related to electricity production. Operation does

not produce carbon dioxide, sulphur dioxide, mercury, particulates, or any

other type of air pollution, as fossil fuel power sources do. Wind power turbines

consume resources in manufacturing and construction. As summary, the following

table presents the estimation in average GHG emission for different

technologies [81].

|

Technology |

g/kWh |

|

Coal |

850 – 1100 |

|

Coal with CCS |

85 – 220 |

|

NG Simple Cycle |

550 – 680 |

|

NG Combined Cycle |

400 – 520 |

|

Geothermal for

Electricity |

40 – 115 |

|

Biomass |

-40 – 40 |

|

Wind |

20 – 55 |

|

Photovoltaic |

40 – 120 |

|

Solar Thermal |

30 – 100 |

|

Nuclear |

20 – 35 |

|

Hydro-electric |

10 – 30 |

Table 5.3: GHG emission by technology

The GHG emission

intensity for the electricity industry in Alberta was 930 g/kWh in 2006 [84].

This means that 10 kW of installed wind power in

Alberta represents an emission reduction of 25.3 tGHG per year, this is

comparable to:

·

5 cars off of the road, or

·

300 fluorescent tubes less, or

·

5,100 toner cartridges not used,

or

·

4,500 people take the bus

between St. Albert and Edmonton, or

·

1,800,000 paper cups of coffee

not used, or

·

2,500,000 A4 sheets not used.

During manufacture of the wind turbine, steel,

concrete, aluminum and other materials will have to be made and transported

using energy-intensive processes, generally using fossil energy sources. The

initial energy "pay back" is claimed by one company to be within

about 9 months of operation for their offshore turbines and the British Wind

Energy Association claim the average wind farm will pay back the energy used in

its manufacture within 3 to 5 months of operation. However, a report to the

British House of Lords in 2004 suggested a payback time of 1.1 years, taking

into account factors such as plant construction and decommissioning. A shorter

period for offshore facilities was given, as the higher capacity factors would

more than offset the added energy costs of installation.

On-roof turbines do

not have environmental concerns for site installation, another impact which that

wind farms must consider.

The following table presents

the estimation in rate of job creation for some technologies [56] for big scale

applications; for micro-generation applications, the factor of increase is

between 10 and 15.

|

Renewable energy |

Construction & installation Ratio per [MWp] |

Operation & maintenance ratio per [MWp] |

|

Wind

|

1.5 |

0.3 |

|

Coal

fired Power Plant |

0.27 |

0.74 |

|

Biomass |

0.4 |

1.4 |

|

NG

fired Power Plant |

0.25 |

0.7 |

Table 5.4: Micro-generation shows great potential as job creator

The stochastic nature of wind is an important constraint

for wind projects and turbine design. The majority of today’s wind turbines

operate within the first 100 m of the earth’s surface. This region, which

occupies the lowest portion of the planetary boundary layer (PBL), is extremely

turbulent and driven by variations, which occur with the diurnal  changes in the atmospheric

boundary conditions. The vertical variation of temperature and wind speed with height defines the PBL

behaviour characteristics. During normal daytime turbine operations, the

temperature normally decreases with height, which contributes to a convectively

unstable atmosphere. Under these conditions, the largest and most energetic

turbulent motions are associated with convective edges or cells that are many

times larger than even the largest wind turbines. The large eddies actively mix

with and absorb the smaller, more compact turbulent structures that have a more

direct impact on rotating wind turbine blades. These effects are increased in

cities were human activity means more temperature variations. Appendix

K presents more details.

changes in the atmospheric

boundary conditions. The vertical variation of temperature and wind speed with height defines the PBL

behaviour characteristics. During normal daytime turbine operations, the

temperature normally decreases with height, which contributes to a convectively

unstable atmosphere. Under these conditions, the largest and most energetic

turbulent motions are associated with convective edges or cells that are many

times larger than even the largest wind turbines. The large eddies actively mix

with and absorb the smaller, more compact turbulent structures that have a more

direct impact on rotating wind turbine blades. These effects are increased in

cities were human activity means more temperature variations. Appendix

K presents more details.

Canadian Wind Energy Atlas

[1] provides a database for the average wind frequency and direction for

Edmonton region. The available data is for three different altitudes: 30, 50

and 80 meters. This database does not take into consideration several

application factors such as wind interaction in urban areas, nozzle effect due

to buildings, turbulence, interaction between obstacles and obstructions, etc. According

to different publications [2][3][4], all those factors increase the wind turbulence

but decrease the average wind speed in building such as NPP and SPP. Based on

this conclusions the database for 50 m is taken.

Wind direction will

have also variations in relationship with the working database. This variation

will not be significantly affected due to the rotation capacity of each wind

generation unit, but it has an effect on the work and energy required in the

control orientation of the turbine.

Figure 5.5: Wind Frequency Orientation distribution for NPP

location 50 m of altitude.

Figure 5.6: Wind Frequency Speed distribution for NPP

location at 50 m of altitude.

Although the useful

database provided by [1], the urbane zone interaction generates distortions of

this frequency distribution and before to start the project measures during a

period of time the real conditions on top of the building is necessary. The

efficiency of the wind turbine is obtained through the composition between this

wind frequency speed distribution and the power curve of each turbine. To know

the real wind conditions on the roof of the building will allow selecting

better turbine and its better operating conditions.

One

of the significant measures of the cost effectiveness of a wind turbine is its

production of energy. In the design and analysis of wind turbines, the annual

energy output is calculated. Calculation of annual energy output requires

knowledge of the wind speed frequency distribution and the system power output

of the turbine as a function of wind speed. Furthermore, every prediction of

annual energy output is specific, depending on the local wind flow patterns and

turbulence and the local air density [19][21].

Turbine height was found

to have a significant effect on mean wind speed and power generated, while

output varied considerably with wind direction. The optimum mounting position

was also found to be dependent on the wind direction. If the probability of

wind flowing from all directions is similar, however, turbine location was

found to be unimportant provided that the turbine was located above roof

height. With a strong prevailing wind direction, optimum mounting position is

likely to vary.

Several factors affect the power

output and efficiency in electricity generation for a turbine; the most

important factor is the correct selection of the turbine for the wind

conditions in the site. The wind condition is a statistic result of the study

during a period of time in the exact location where the turbine will be

located. For on-roof projects, this study presents a big concern that must be

specially considered. Many factors affect the wind frequency distribution and

intensity in cities and they change over the time.

Urban wind monitoring projects in Europe, the UK

and the USA consider the future viability of roof-top turbines in urban houses,

the advantages and disadvantages of the systems, and compare yield and noise

from alternative models. The WINEUR project and Warwick wind trails are based on 21 building

mounted turbines each, while the Massachusetts trial is based on 19 small

turbines in urban locations [79]. Both the Warwick and Massachusetts projects

found that urban site conditions that reduce wind speed are not the sole reason

for low energy production. The accuracy of manufacturers’ power curves, losses

from balance-of-system components, and losses from additional site conditions

(such as very close obstacles causing turbulence and wind shear), have also

been identified as major causes. The balance-of-systems and effect of

turbulence/wind shear are estimated to reduce energy production by 10–15% and

15–30%, respectively. The following figure shows both

typical curves for different analysed turbines and the annual wind speed

frequency distribution for above NPP respectively.

Figure 5.7:

typical curves for different analysed turbines and the annual wind speed

frequency distribution on NPP.

The following figure shows the

estimated efficiency for each turbine in Edmonton NPP in on-roof project. This

efficiency takes into consideration the different loss of efficiency due to mechanical

and electronic losses in transmission, conversion, insects, ice, etc. The net

delivered energy by the turbine should be considered for comparison of

technologies, the development of the business case and any other study or

comparison.

Figure 5.8: Total energy

efficiency estimation for the analysed turbines considering the on-roof

application in NPP. The average value, 20.5%, is shown as the red line.

-

Total efficiency higher than 20% is anticipated for efficiency

specifications.

The overall cost for the wind turbine project is

determined by the manufacturing costs, the amount of captured energy, the cost

for site preparation and installation, the maintenance cost and the financing

cost [40]. It is measured in $/kWh. Technical factors such as the efficiency of

the turbine, the efficiency of drive train, generator and grid connection also have

an important impact on the cost.

When comparing the manufacturing costs of VAWTs and

HAWTs, consider that the HAWTs have been produced for a long time and are

produced in large numbers. As result smarter and cheaper solutions and the

large numbers produced decreases the price since parts can be mass produced.

Furthermore, as the technology has matured it has been possible to scale up the

HAWTs, lowering the cost per installed kW even more. No mass production of

VAWTs exists.

The difference in costs between VAWTs and HAWTs for

planning, producing, transporting and erecting a turbine and for operation and

maintenance (O&M) is mainly governed by the different costs for producing

the turbine and the costs for O&M with some exceptions; it might be easier

to erect the lighter tower of a VAWT, and it might be easier to transport the

shorter blades of a HAWT, whereas the curved blades for the Darrieus turbine is

very difficult to transport.

The efficiency for VAWTs is expected to nearly

reach efficiency values for HAWTs

[40]. The design of the H-rotor is based on simplicity. By omitting a yaw

system and the heavy nacelle and by having straight blades, the production

costs are lowered even though the H-rotor usually has longer blades than a

HAWT. For a Darrieus turbine, the blades are expensive to manufacture since

they are both long and bent and sometimes twisted. The cost analysis made by

Walters et al. [47] indicates

that VAWTs could be cost competitive to HAWTs.

The following figure shows the range of cost per kilowatt

nominal capacity:

Figure 5.9: Cost of wind project per kW of nominal capacity

Since

the majority of the world’s population lives in urban areas, implementing wind

turbines for electricity micro-generation for urban houses has the potential to

make a significant contribution to renewable energy targets. Micro-generation

at the single-building scale using roof-top wind turbines is one technology

being used on urban houses increasingly in European cities and just starting in

Canadian cities.

Typical roof-top turbine installations for houses

are rated at 3.5 kW or less. In Alberta, a 2.5 kW nominal capacity turbine is

enough to provide the consumed electricity for the average household. A study

of 21 roof-top turbine installations in Europe under the WINEUR project has revealed that the reasons

for installing turbines vary from educational (46%) and environmental (26%) to

improving the organisational image (20%). Thirty percent of these turbines were

installed in villages or country parks, while only 10% were installed in dense inner-city

locations [79].

To date the low development of roof-top turbines in

relationship with wind farms is related with the lower efficiency, high cost

per nominal kW for the small turbines, particularities for each application, and

a lack of policies that help with the development of the micro turbines market.

All these barriers are being minimized over time with the introduction and

development of new technology and adequate policies such as Alberta’s micro-generation

regulation.

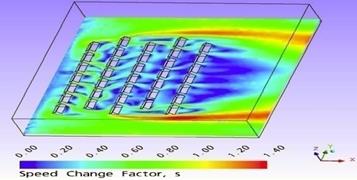

Computer simulations used to study wind flow in an

urban area around an array of simple pitched-roof buildings, along with the

effect of potential turbine mounting position on the turbine output, found that

the behaviour of wind in a built-up area is different from that around an

isolated house. For example, the speed-up effect as wind passes over the ridge

of an isolated house is absent when the house is in an urban environment. Appendix

L summarizes different on-roof projects around the world.

Unlike

many conventional energy generating sites, on-roof wind turbines do not require

expensive decommissioning or remediation when they cease operation. Also, on-roof turbines are small turbines and their decommissioning

does not require special considerations.

Decommissioning will occur if leases are not

renewed at the end of the term. Full removal of all equipment and foundations

and the site remediation will be completed, to the satisfaction of the

landowner as stipulated in the lease agreement, and in compliance with all

federal, provincial, municipal and building regulations.

This

section identifies potential health and safety risks to the public from the

construction and operation of the Project.

Noise

With little consideration of low

frequency noise standards, which vary from country to country, the inadequacy

of Michigan’s wind turbine noise standard becomes apparent when reviewing

general noise level standards

for

community noise and wind turbine noise that have been adopted around the world.

The Michigan Wind Guidelines states 55 dBA. Michigan Standards also exceed

regulatory limits set in Denmark, the Netherlands, Germany and New Zealand,

which have not been included here.

|

District type |

Daytime limit [dBA] |

Evening limit [dBA] |

Night limit [dBA] |

|

Rural |

35 |

30 |

25 |

|

Sub-urban |

40 |

35 |

30 |

|

Urban residential |

45 |

40 |

35 |

|

Urban mixed |

50 |

45 |

40 |

Table 6.1: ISO 1996-1971 Recommendations for

Community Noise Limits

Icing

Icing presents an

important concern due to the weather conditions for the turbine location. The

lack of regulation about wind turbine icing presents more challenges for this

project located in Edmonton.

Aircraft

Routes

One

of the major constraints for developing the on-roof project in Edmonton

downtown is the aeronautical regulations due to the Edmonton City Centre

Airport. NPP and SPP are in the protected zone for air traffic and the

regulations introduce serious limitations in lighting, colour and maximum

height.

Figure 6.1: view of Edmonton

City Airport and NPP and SPP buildings

The

minimum distance between NPP and the south runways of the airport is around 2,500

meters. This is the minimum required distance for many security navigation

regulations. The analysis should carry on with precaution. The evaluation

process has already started.

The authorization request should be

completed for new structures only if:

·

The structure

is within six (6) kilometers of the center of an aerodrome, or two (2)

kilometers of a TC radar, radio navigation or radio communication antenna; or

·

The structure

exceeds twenty (20) meters in height, including catenary wire crossings; or

·

The structure

is within fifteen (15) meters and exceeds the height of a dominant structure

already in place.

Lightning

Due

to the height of the turbines, there is a potential for lightning strikes.

Navigation Canada provides the guidelines for lighting.

Transport Canada: http://www.tc.gc.ca/ontarioregion/civilaviation/aerodrome/documents/ObstructionclearanceForm.PDF

http://www.tc.gc.ca/CivilAviation/Regserv/Affairs/cars/PART6/images/g621s07.gif

http://www.tc.gc.ca/CivilAviation/Regserv/Affairs/cars/Part6/Standards/Standard621.htm

Aeronautic Act: http://laws.justice.gc.ca/en/A-2

Micro Generator Application - Process & Guidelines: http://www.auc.ab.ca/aucdocs/programs/MicroGen/Micro_Generator_Application_July%2018.pdf

Micro-generation

Regulation: http://www.auc.ab.ca/aucdocs/programs/MicroGen/Microgen_Regulation.pdf

FAQ: http://www.auc.ab.ca/aucdocs/programs/MicroGen/micro_gen_faq.pdf

Forms: http://www.auc.ab.ca/aucdocs/programs/MicroGen/Forms.doc

Wire

Service Provider: http://www.ucahelps.gov.ab.ca/9.html

Alberta

Transportation: http://www.transportation.alberta.ca/Content/docType329/Production/rdpapp.pdf

Hydro and

Electric Energy Act: http://www.qp.gov.ab.ca/documents/Acts/H16.cfm?frm_isbn=9780779730209 http://www.qp.gov.ab.ca/documents/Regs/1983_409.cfm?frm_isbn=0773236775

Legal Land Description: http://www.servicealberta.gov.ab.ca

The City of Edmonton

bylaw 14600 states the following limit for noise generation:

·

Daytime decibel limit – non residential:

o

75 dBA

between 7 a.m. and 10 p.m

o

80 dBA

lasting for a total period of time not exceeding two hours in any one day; or

o 85 dBA lasting for a total period of time not

exceeding one hour in any one day.

·

Overnight decibel limit – non residential:

o 60 dBA before 7 a.m. or after 10 p.m.

Based on the research done a wind turbine would not exceed

these limits.

Municipal

Affaires : http://municipalaffairs.gov.ab.ca/

Edmonton Airport:

Negotiations with the

building owner should be started one the project is approved. The project adds

value to the building (e.g. provide credit for LEED qualification), but studies

should be carry on to the changes in static and dynamic load in the building.

Four different

scenarios are proposed for a comparative analysis:

-

The first scenario is called status-quo; it represents not

developing any project and to promote MG through advertisement, brochures, etc.

as is the current practice.

-

The second scenario is called on-roof H/VWAT (On-roof wind);

it represents the development of on-roof project based on HAWT or VWAT

technology on NPP and SPP buildings (preferably but not limited to).

-

The third scenario is called HWAT (Ground wind), it represents

the development of windmill project on river ground.

-

The fourth scenario is called Solar Panel; it represents

the development of on-roof project based on Solar Photovoltaic (PV) panels on

NPP and SPP buildings (preferably but not limited to).

Researchers had

studied, proposed indexes and assessed the different renewable sources of

energy for electricity generation [29][30][48][49][50][51][52][53].

Some of these assessments could be applied for Alberta’s conditions in the

comparison for this project. In [29] [30] the non-combustion

based renewable electricity generation technologies were assessed against a

range of sustainability indicators, using data obtained from the literature. The

conclusion (Alberta conditions are usually worse for renewable electricity

production), according to the second paper our electricity generation is:

|

Technology |

Sustainable rankings |

|

|

Wind |

13 |

|

|

Hydro |

16 |

|

|

Solar |

20 |

|

|

Geothermal |

21 |

|

Table 7.1: Sustainable ranking for

different technologies

The conclusion of this paper shows

that wind technology has the best ranking assessment, followed by Hydro, PV and

Geothermal. PV has 54% worse ranking than wind technology for our climate and

location. Wind technology also shows better index in Price, GHG emission, availability

and limitations, efficiency, water consumption and social impact; the only

index that PV overcomes wind is in land use.

Quite often citizens,

journalists, policymakers and politicians are bombarded for information showing

the useful of solar technologies, geothermal for power, etc; usually, the

information does not include details which adapt the technology for Alberta conditions

(sun radiation intensity, grid emission, depth of resources, etc). Alberta’s

conditions are significantly worse for solar technologies than the average

condition studied in the assessment, and these indexes show more differences in

our country.

PV technology is an

excellent technology, but for very specials applications today. The future

appears to be better if some milestones are reached and barriers overtaken for

the development of the technology. Also, today this technology needs of

external conditions to see it massively used; one of the most important is the

increase of fossil fuel prices.

Nowadays, PV technology looks to be very expensive

and inefficient for common application in comparison to other technologies,

especially in Alberta (and Canada). PV systems offer the promise of clean and

plentiful energy, but they suffer a large handicap in that their cost is still

much too high. Nevertheless, during the 1980s and 1990s PV cell production has

been increasing on average by more than 15% per year.

Appendix M provides details of solar photovoltaic technology

analysis.

All scenarios must be

developed in similar and real conditions in Alberta regions, focusing on downtown

buildings in big cities. The magnitude of the evaluation is:

|

Negative |

|

Positive |

||||

|

High |

Medium |

Low |

Neutral |

Low |

Medium |

High |

|

-3 |

-2 |

-1 |

0 |

1 |

2 |

3 |

Table 7.2: Assess impact evaluation table

Where:

- High: impact is significant and stakeholders support and

preparation are critical

- Medium: manageable impact to the stakeholders

- Low: minor impact to the stakeholders

- None: stakeholders will not be impacted

|

Subject |

Stand-by |

Solar

Panels |

On

roof Wind |

Ground Wind |

|

Energy use and conservation |

0 |

1 |

2 |

1 |

|

Energy efficiency promotion |

0 |

1 |

2 |

1 |

|

GHG emission reduction |

0 |

1 |

2 |

2 |

|

DoE commitment and initiative |

-1 |

2 |

3 |

2 |

|

Micro-business development |

1 |

2 |

3 |

3 |

|

Show case for MG technologies |

0 |

1 |

3 |

3 |

|

Quality investment |

-3 |

-2 |

2 |

2 |

|

Risk |

0 |

-1 |

-1 |

-1 |

|

Impact Score |

-3 |

+5 |

+16 |

+13 |

Table 7.3: Assess impact evaluation for the different four

alternatives

Risk assessment consideration:

·

Probability

of risk:

o

High:

highly likely to occur

o

Medium:

likely to occur

o

Low:

not likely to occur

·

Impact

of Risk

o

High:

significant impact to the project

o

Medium:

impact the project

o

Low:

impact is relatively minor to the project

o

None:

will not impact the project

|

Impact |

High |

3 |

-3 |

-6 |

-9 |

|

Medium |

2 |

-2 |

-4 |

-6 |

|

|

Low |

1 |

-1 |

-2 |

-3 |

|

|

None |

0 |

0 |

0 |

0 |

|

|

|

|

-1 |

-2 |

-3 |

|

|

|

Low |

Medium |

High |

||

|

|

Probability |

||||

Table 7.4: Risk

assessment table

Appendix N presents

the detailed risk analysis for each alternative.

|

Risk Impact |

Stand-by |

Solar Panels |

On-roof Wind |

Ground Wind |

|

Total Risk |

-6 |

-26 |

-18 |

-18 |

Table 7.5: Risk assessment outcome

for the four different alternatives

RETScreen

software, by NRCan, provides a comparison tool between Solar Panel and Wind

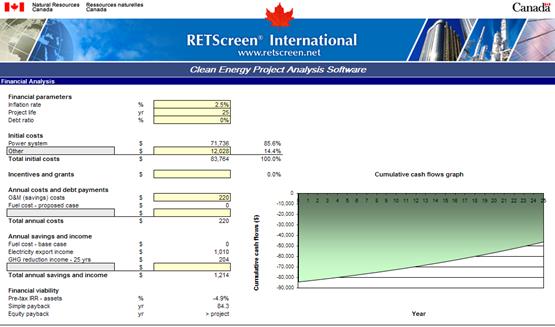

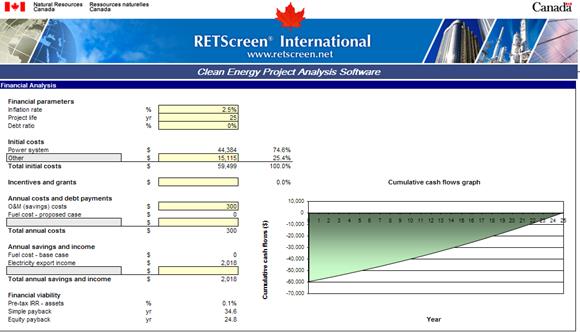

alternatives. Appendix

O presents the RETScreen Finanacial analysis output.

|

Re-directing promotion budget |

Stand-by |

Solar Panels |

On-roof Wind |

Ground Wind |

|

Nominal capacity [kW] |

na |

8 |

8 |

8 |

|

Electricity generation [MW/y] |

na |

8.4 |

17 |

15 |

|

Total Initial Cost |

~40,000 |

83,764 |

59,499 |

57,720 |

|

Annual Cost |

0 |

220 |

300 |

300 |

|

Simple Payback [y] |

na |

54.1 |

17.2 |

16.1 |

|

Equity Payback [y] |

na |

35.4 |

14.2 |

13.4 |

Table 7.6: RETScreen summary for

the ecominic comparison of the four alterantives

As Wind

Turbines and Solar Panels contribute significantly to micro-generation

promotion, business cases are developed where the 75% of the micro-generation

funds for Stand-by alternative are used as promotion in the other alternatives.

|

Re-directing promotion budget |

Stand-by |

Solar Panels |

On-roof Wind |

Ground Wind |

|

Nominal capacity [kW] |

na |

8 |

8 |

8 |

|

Electricity generation [MW/y] |

na |

8.4 |

17 |

15 |

|

Total Initial Cost |

~40,000 |

53,764 |

29,499 |

27,720 |

|

Annual Cost |

0 |

220 |

300 |

300 |

|

Simple Payback [y] |

na |

54.1 |

17.2 |

16.1 |

|

Equity Payback [y] |

na |

35.4 |

14.2 |

13.4 |

Table 7.7: Reasignation of funding for the RETScreen summary for the ecominic

comparison.

The Assess Impact assessment shows that Wind Turbine is the

better project in comparison to Solar Panels and Stand-by alternatives.

|

Assess Impact |

Stand-by |

Solar Panels |

On-roof Wind |

Ground Wind |

|

Impact Score |

-3 |

+5 |

+16 |

+13 |

The Risk Impact assessment shows that Stand-by alternatives

has a lower risk, followed by Wind Turbine alternatives.

|

Assess Impact |

Stand-by |

Solar Panels |

On-roof Wind |

Ground Wind |

|

Total Risk |

-6 |

-26 |

-18 |

-18 |

Economic assessment

shows that Wind turbine alternatives are abetter as business case in comparison

to Solar Panels and Stand-by alternatives.

|

Economic assessment |

Stand-by |

Solar Panels |

On-roof Wind |

Ground Wind |